THANK YOU

for purchasing the ND MX-5 Miata Temperature and Pressure Conventional Gauge Kit from CravenSpeed. This product is made from the highest grade materials, and is guaranteed to be free from defects.

You can buy our

CravenSpeed Classic Gauge Kit for ND MX-5 Miata here

NOTE:

This install may seem a bit intimidating at first glance, but honestly it is fairly simple and straightforward. Just read through the instructions completely beforehand and take your time. If you are unsure of your mechanical abilities, please seek out a friend that can assist you or a professional shop that can complete this install for you.

We recommend that you perform this upgrade when the vehicle is cool, as you’ll be in the vicinity of potentially hot engine components and will come into contact with engine oil.

Lastly, this would be a great time to perform an oil change to your car as we will be opening up the oiling system. If you still have many miles left on your current oil service, utilize a new/clean drain pan so that you may put the drained oil back into your car after the install is complete.

1. We will be going underneath the car for this installation, so let’s begin by placing wheel chocks behind the rear wheels and setting the vehicle up on jack stands. Your work surface should be solid and as level as possible. Do not perform this installation on uneven, soft ground or any surface where stability could potentially be an issue. Above all, stay safe!

2. Once you have the car in the air and have determined that it is safe and stable, slide underneath the vehicle with your 12mm socket and ratchet wrench. We will need to remove the aluminum panel under the engine just aft of the front wheels. There should be (9), 12mm bolts around the perimeter of the panel attaching it to the car.

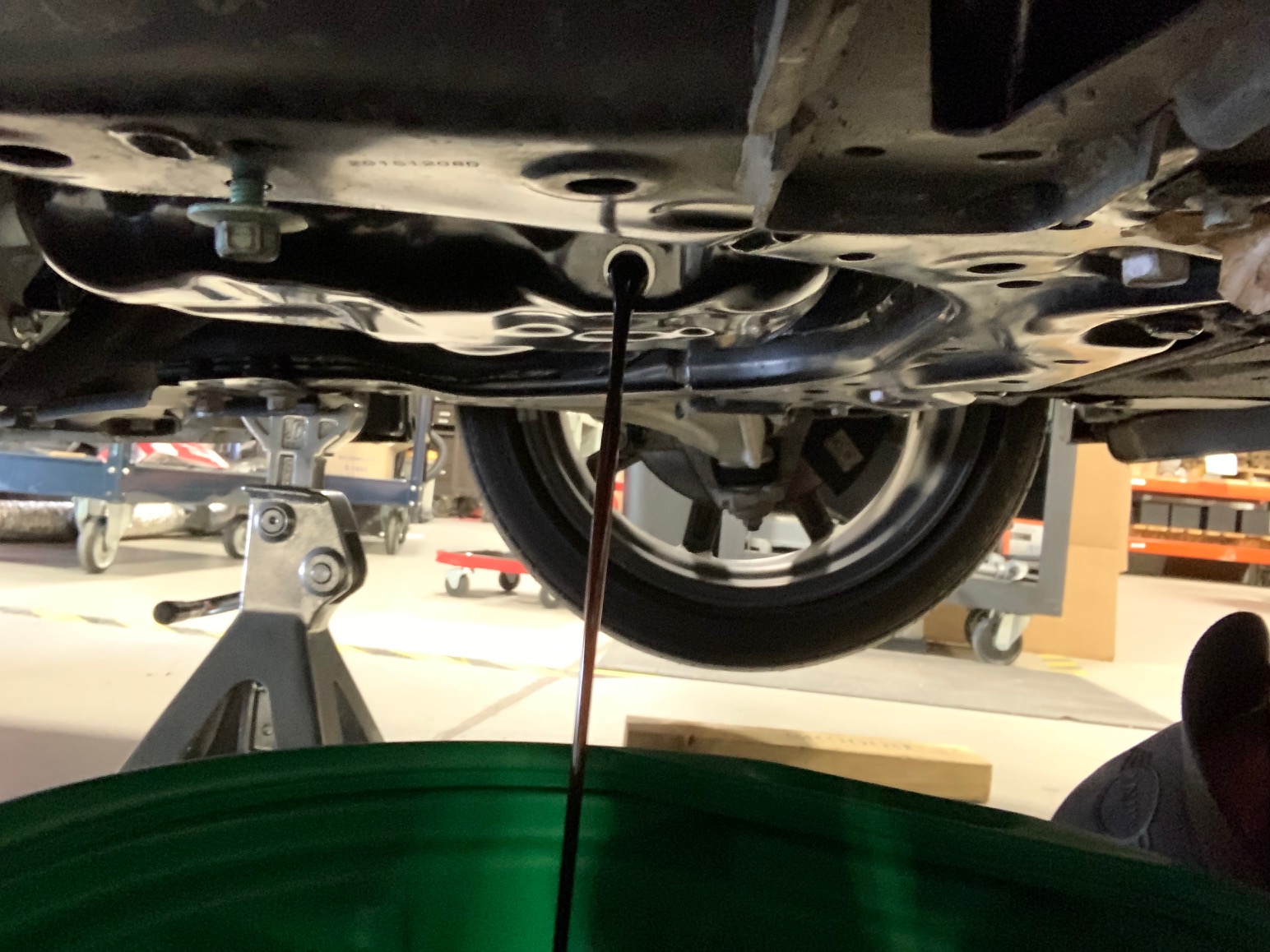

3. We will be installing the sender adapter between the engine oil filter adapter and the engine block. Removing this oil filter adapter opens up the oiling system, so we're going to need to drain the oil out of the engine.

4. Slide out from under your car and pop open the hood. Remove the oil filler cap and set it next to the inlet. Go back under your car with your oil drain pan in tow and place it under the oil drain plug. Utilizing your 8mm hex wrench, remove the drain plug and drain the oil. Once the oil has drained out, replace the drain plug, tighten it and slide the oil drain pan out from under the car.

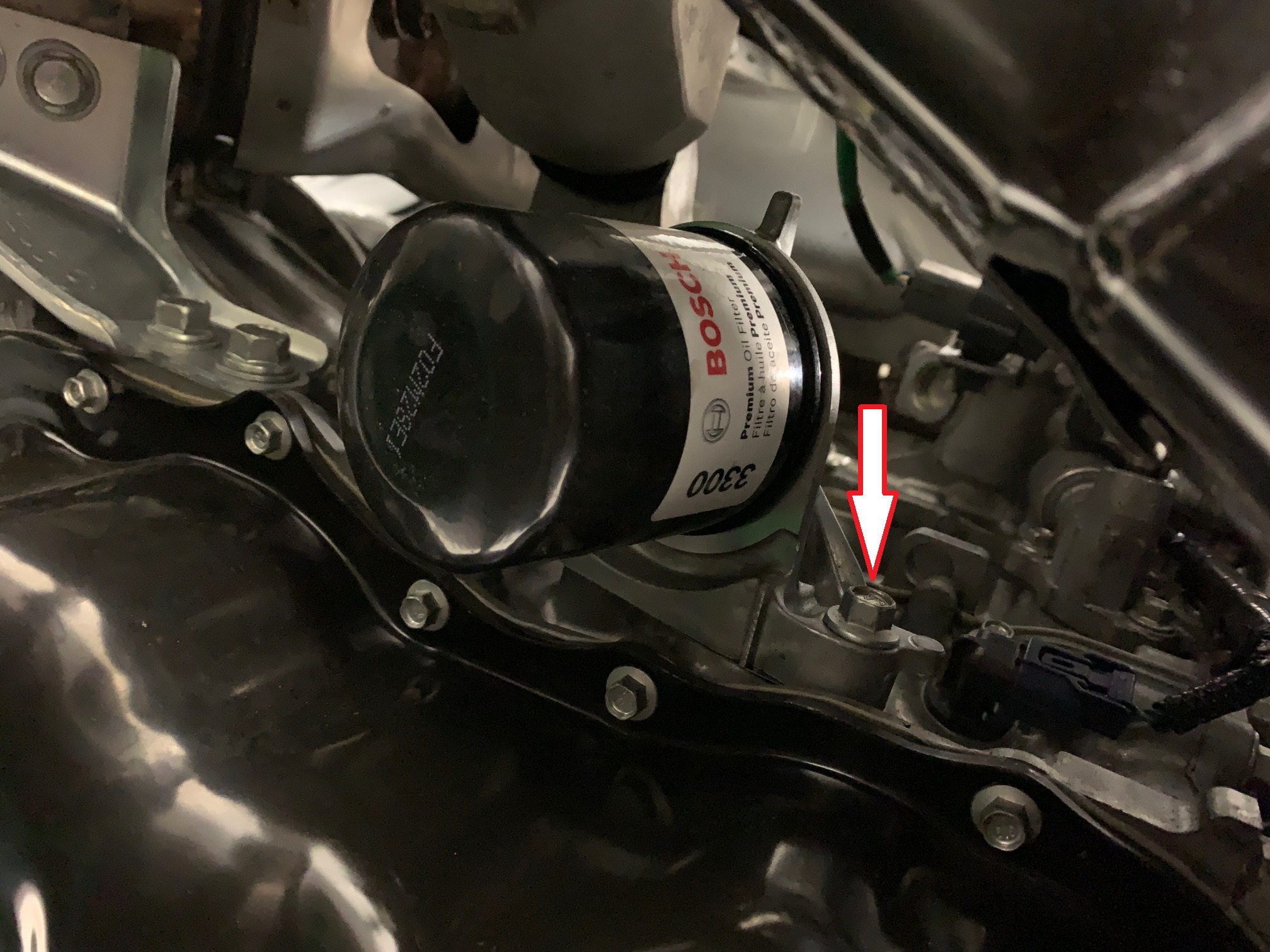

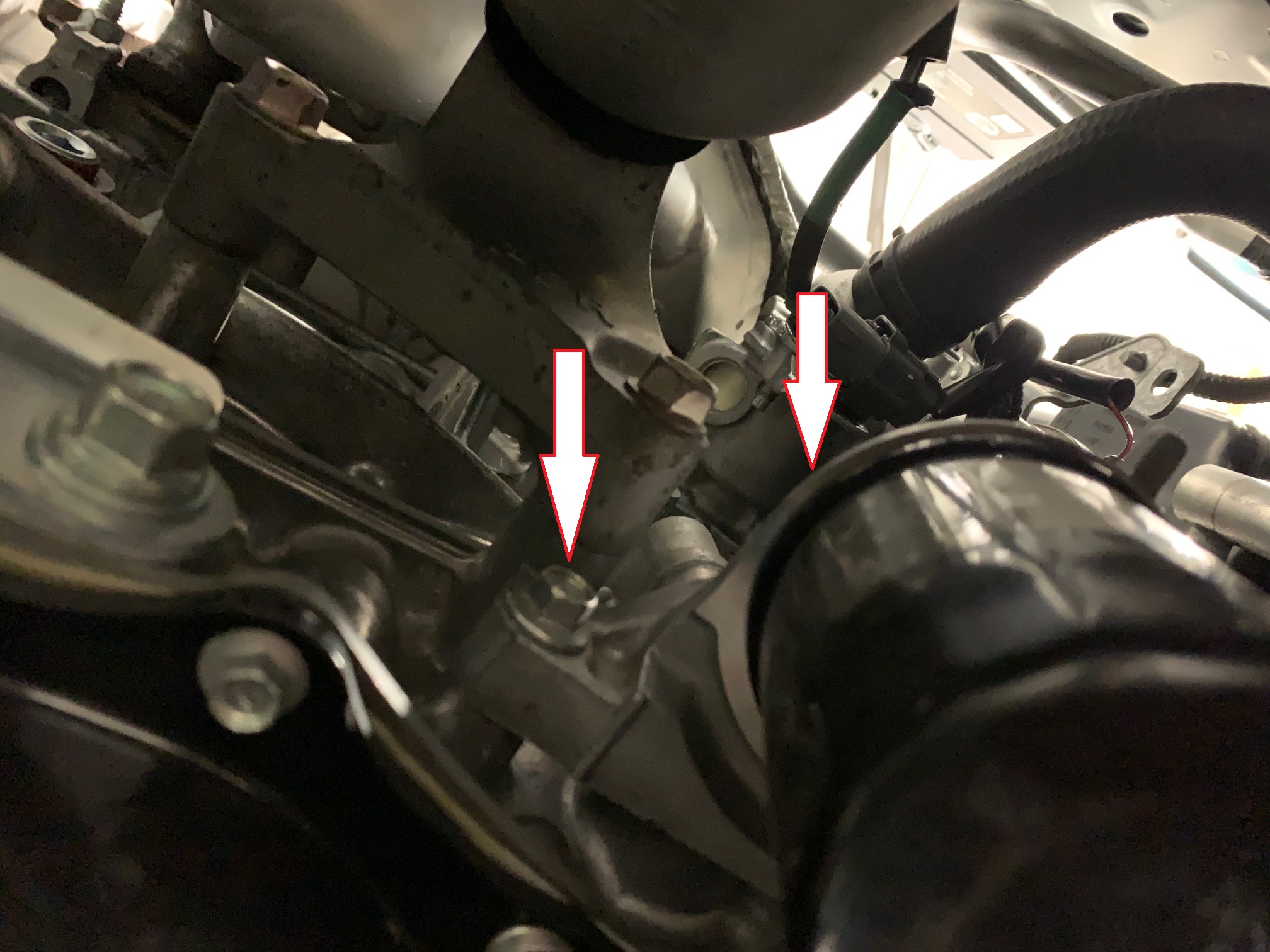

5. Locate the engine oil filter adapter and use a 10mm socket wrench to remove the three screws holding it to the side of the engine block. Have a couple shop towels handy so you may minimize the oil spillage.

6. The factory gasket for the oil filter adapter is metal with no sealant, so it should come off with minimal effort. Do not damage or throw away this gasket as you will be reusing it for the install of this component.

7. Take the CravenSpeed Tapless Temp and Pressure Adapter and install the o-rings into their respective locations. The two smaller ones go into the round grooves while the larger o-ring is placed into the oblong groove.

8. We recommend that you install your gauge sending units into the Tapless Adapter before you install it onto the engine. Take note of the port markings so that you install the senders into their proper locations. We have also provided two (2) 1/8" NPT plugs in case you decide to install your gauge sending units at a later date.

9. Place the CS tapless adapter with the 'o-ring side' against the engine block. The factory metal gasket goes against the flat side of the tapless adapter followed by the oil filter adapter and the three longer screws provided. Tighten these screws with your 12mm socket wrench.

10. Refill your engine with factory specified motor oil, replace the filler cap, and turn it on to check for leaks. Make any adjustments if necessary.

11. If everything checks out ok, head back under and hookup your sender wiring. Each Marshall gauge will come with it's own crimp connectors for the senders and CravenSpeed provides the necessary lengths of

Green

signal wire to run from the senders into the interior of the car. A ground wire hookup is also required for both senders and you may combine the two to the same ring terminal for grounding purposes. From the

Black

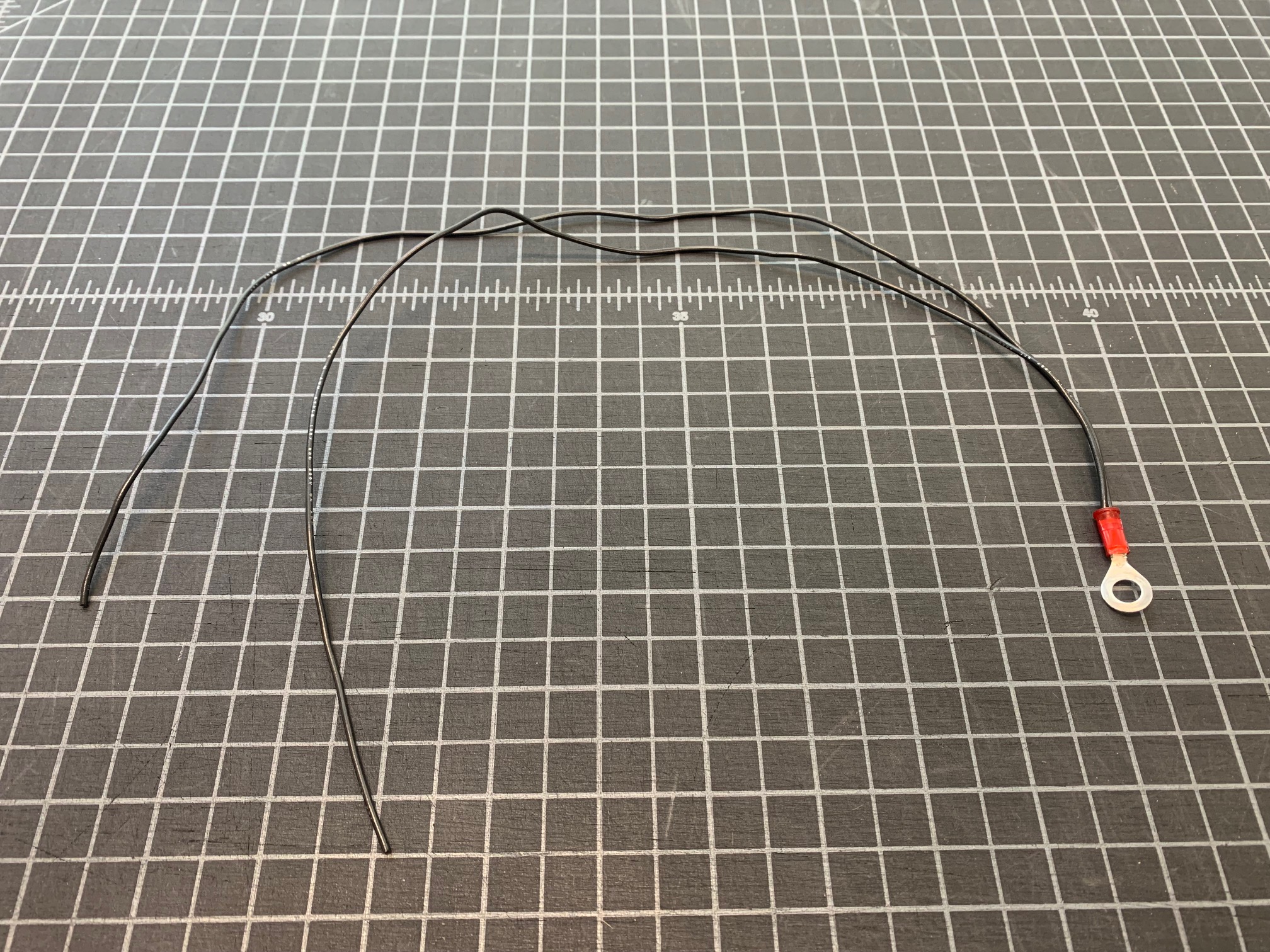

wire provided, cut two (2) 18" lengths and on one end, crimp on their respective terminals and on the other end twist the leads together and crimp on a ring connector for the ground.

12. After connecting the ground wires to the gauge senders, bring the ring-terminal end up alongside the engine and install it onto this bracket. Remove the 10mm nut, add the ring terminal and replace the nut. Ziptie the wires out of reach of any spinning or hot engine components.

13. Next step in this installation process is to install the 2x Vent Gauge Mounts. Please follow this link to view the

CravenSpeed ND MX-5 Vent Gauge Pod Mount

installation instructions. You may also refer to the

Marshall Gauge Wiring Diagram

for more in-depth information regarding the wiring of these gauges than what is provided within this guide.

14. When working on any part of the vehicle’s electrical system, it is always good form to disconnect the negative terminal from the battery to eliminate any possibility of accidental shorts or getting zapped. Pop the hood and do this now.

15. Open the driver side door and remove the door sill trim with your trim panel removal tool or similar non-scratching pry tool. It just disconnects straight up and off. You may even be able to just grasp it with your hands and pull up. Some of the clips may remain attached to the sheet metal of the car. Just pry them out and reattach to the bottom of the sill trim.

16. Remove the driver side kick panel. There is a plastic push-pin connector just forward of the fuse panel access hatch. A trim panel tool comes in handy here as well. Once the pin is popped off, peel the lower portion of rubber door seal off the pinch seam and pull the kick panel towards the back of the car. It should release without much effort.

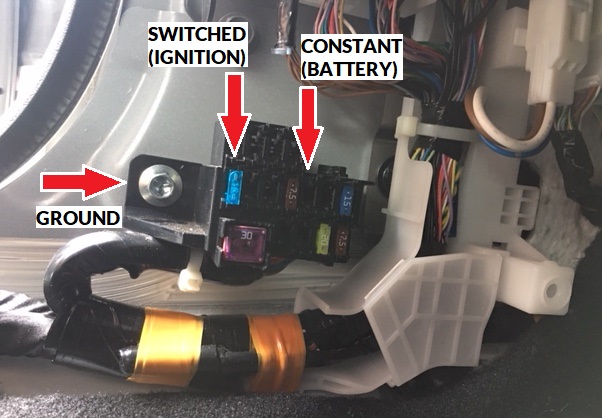

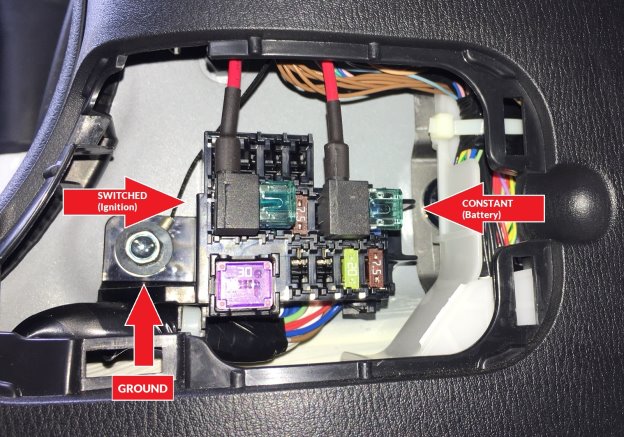

17. This will expose the fuse panel and allow access to the firewall behind the dash and routes for your gauge wiring. We’ll use the fuse slot locations shown in the image below for your power sources. The blue 15 amp fuse slot on the left is your switched power (ignition) and the empty slot just to the right of the brown 7.5 amp fuse will be your constant (battery). Your gauges will require power from both sources and they will share the power leads from each source (switched and constant). The 10mm screw to the left of the fuse panel will be your shared ground from the gauges.

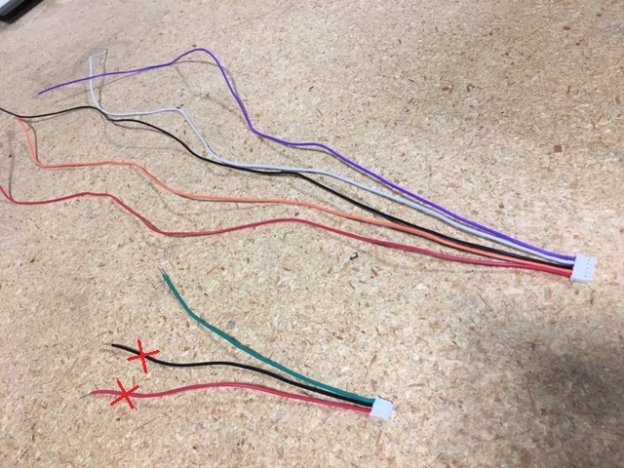

18. Open up the box that the Marshall gauge comes in and remove the wiring pigtails located at the bottom of the clamshell packaging. Separate them and set aside the 5-wire plug (Purple, White, Black, Orange, and Red) and the 3-wire plug (Green, Black, and Red).

19. The wire callouts are as follows: 5-wire pigtail;

Purple

= Constant Power (Battery),

White

= LEDS (white gauge backlighting illumination),

Black

= Gauge Ground,

Orange

= LEDs (orange gauge backlighting illumination), and

Red

= Switched Power (Ignition). The 3-wire pigtail is;

Green

= Signal lead to sending unit (Temp or Pressure Sender). The

Black and Red

wire are not used in this install, so you may trim them flush at the plug or just snip the exposed wire at the end and wrap a little electrical tape around them.

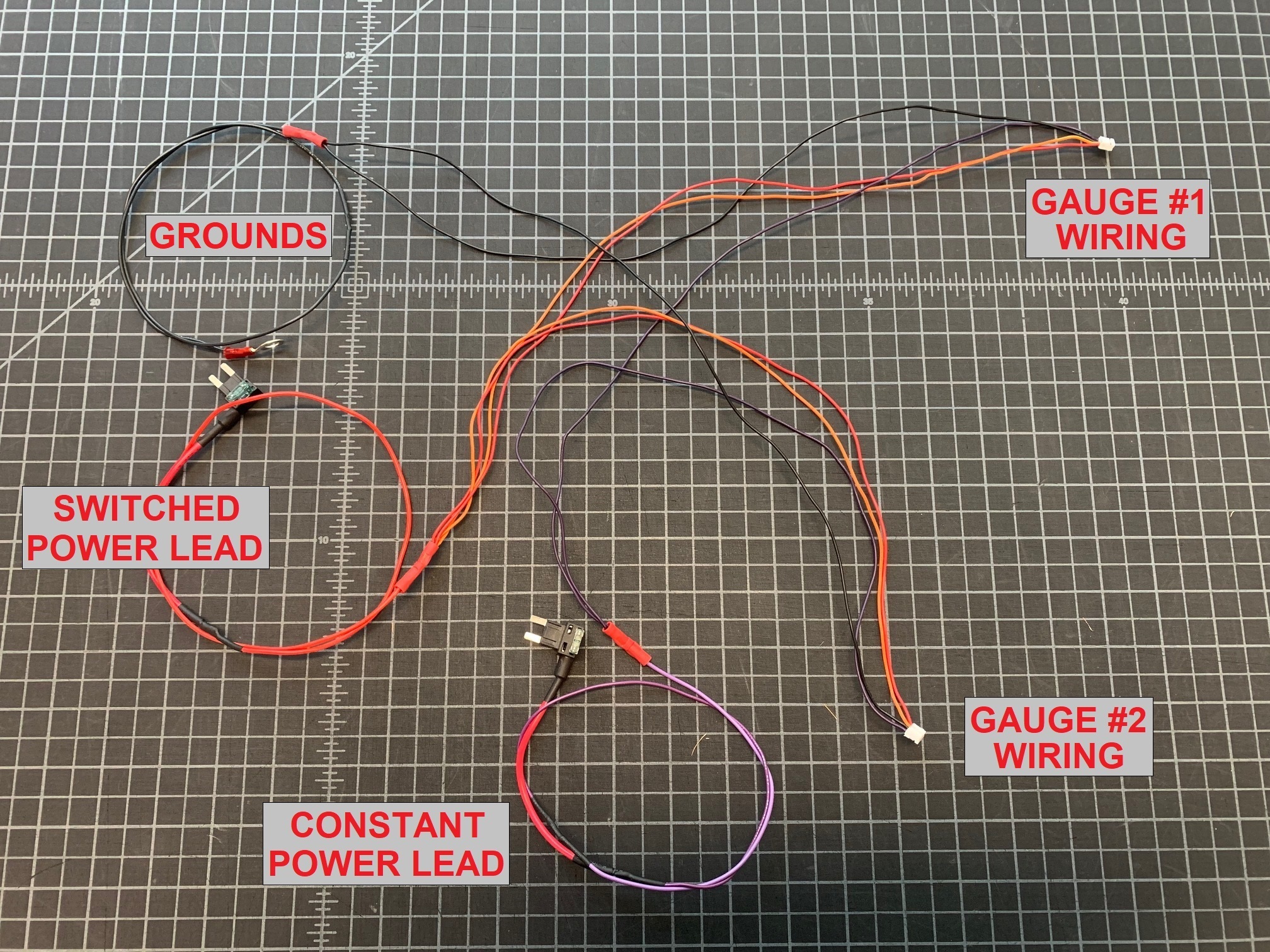

20. Lay out the two (2) 5-wire pigtails from both gauges onto your work surface. We will be combining leads together from both pigtails to share power sources, backlighting options, and ground. Twist the two

Red

wires together (switched ignition) along with either the

White or Orange

leads (gauge LED backlighting color) the and crimp a butt-splice connector to the end. On the opposite end of this butt-splice connector, add a 2 ft length of the provided

Red

wire. These wires share the power from the switched source to power both the gauges functionality and the backlighting when the car is switched on and running. Perform the same process to the

Purple

wires. Combine>crimp butt-splice>2 ft of

Purple

wire. Perform the same process to the

Black

ground wires. Combine>crimp butt-splice>2 ft of

Black

wire, but crimp a ring terminal to the end of this combination.

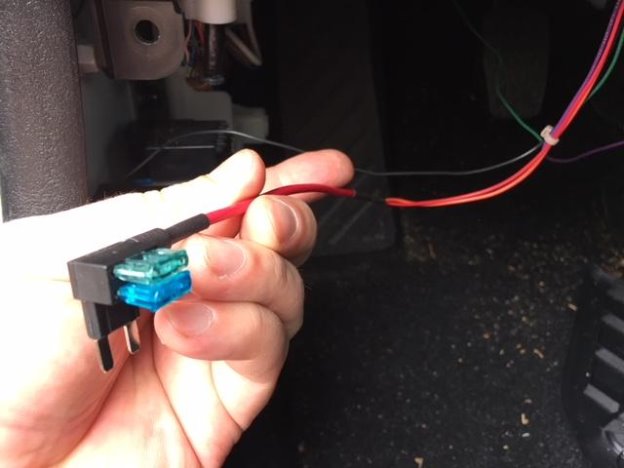

21. Now let’s connect our ‘Add-a-Circuits’. The

Purple

wire from the 5-wire pigtails gets connected (crimped) to an ‘Add-a-Circuit’ and then install one of the provided 1 amp mini fuses into the top slot. For the remaining ‘Add-a-Circuit’, connect it to the

Red

wire from the 5-wire pigtails and add the remaining 1 amp mini fuse to the top slot.

NOTE:

The image below shows the

Orange

LED wires being utilized with the

White

LED wires removed from the assembly.

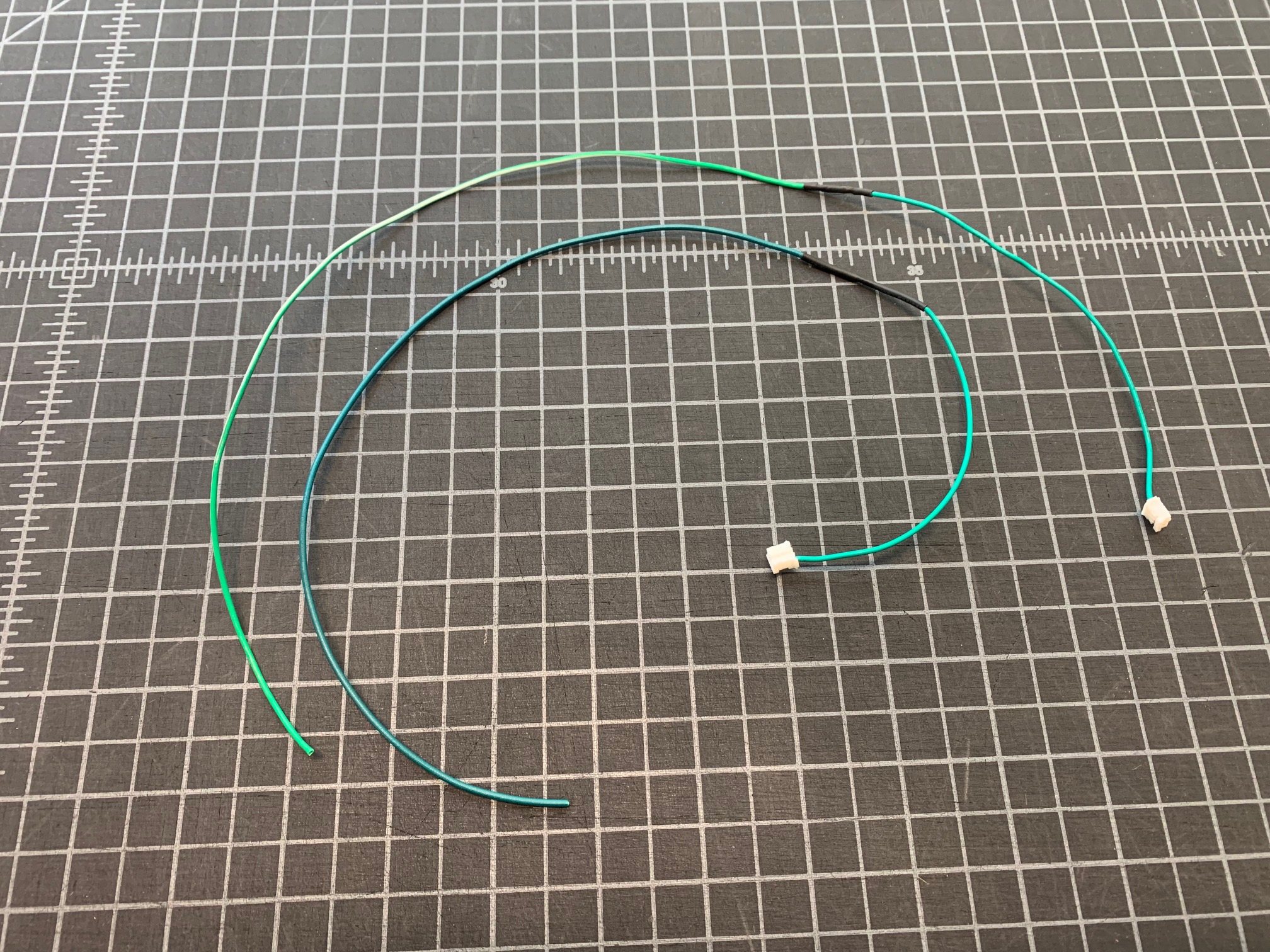

22. 20 ft of

Green

wire is provided with the kit, but you’ll need to trim off two (2), 12" lengths to add to the 3-wire pigtails. Again, the

Red and Black

leads from the 3-wire pigtails are not used, so trim the exposed wires and wrap them with electrical tape. Alternatively, you may remove them from the plug altogether as shown in the image below.

23. For each gauge, combine the 5-wire pigtail and the 3-wire pigtail together within the wiring loom tubing provided (cut into two equal length pieces) and work the sleeved wires up through the dash from the underside between the adjustable steering column and the dash. Fish the wire pigtails through the back of the gauge cup and plug the 5-wire pigtail into the lower 5-pin receptacle on the back of the Marshall gauge and the 3-wire pigtail into the receptacle just beside it.

24. With the pigtail leads plugged into the back of the Marshall gauge, insert the gauge into the gauge cup and slide the ABS ‘half-moon’ cover onto the gauge mounting studs. Thread on the thumb nuts that came with the Marshall gauge. If the mounting studs seem a little long to you, utilize a rotary tool with a cut-off wheel and trim them to a more tidy length.

25. Now organize the ends of the wiring assembly with the 'Add-a-Circuits' and the ring-terminaled ground and work them over to the fuse box area. Locate and remove the blue 15 amp fuse in the switched power slot and place the 15 amp fuse into the lower slot on the switched power ‘Add-a-Circuit’ (red lead from gauge pigtail). Plug this ‘Add-a-Circuit back into the same slot on the fuse panel. Next, take the constant power ‘Add-a-Circuit’ with the 1 amp fuse you installed earlier (purple lead from gauge pigtail) and plug it into the empty fuse slot just to the right of the brown 7.5 amp fuse shown in the following images.

26. There is a 10mm screw located just to the left of the fuse panel which we will use for our gauge ground lead (black wire with ring terminal). Remove the screw, place the ring terminal onto it and reassemble.

27. The only wires left to connect are the green signal leads from the pigtails coming from the Marshall gauges. If you have the green signal wires from your gauge senders already installed through the firewall, use a butt-splice connector and crimp the two wires together (green pigtail gauge wire to green signal wire from gauge senders). Ziptie the wires under the dash so they are tucked out of the way and tidy.

NOTE:

If you do not have your green signal wires from your gauge senders coming in through the firewall, follow the next steps.

28. The oil temperature gauge will have a sending unit with a probe on one end and two wire leads on the other. The black wire is your ground and the white wire is your signal sending wire.

29. The oil pressure sender will look similar to the image below. The two blade terminals on the sender housing are different widths, so take note of this when crimping the connectors onto the proper wires.

30. You should still have 18 ft length of green wire, so cut it into 2 equal length pieces of 8 ft each. Crimp the correct connector included with the Marshall gauge packaging onto your green wire and plug it into the white wire connector of the temp sender and then the same with the (S) blade terminal of the pressure sender.

Take note of the orientation and size of the plugs and don’t mix them up.

PLEASE NOTE:

In the following images, the signal wire used in our installation is

orange

. Your signal wires will be

green

.

31. Bring your two 9 ft green signal leads up and along the front core support of the vehicle, looping them behind the battery and then along side of the corrugated wiring loom. Ziptie the green wires in a few strategic locations to keep it out of the way of moving belts or components that may get hot.

32. Up at the driver side of the firewall there will be a rubber junction that the wiring loom travels through. There is a little molded ‘nub’ just above and to the side that we’ll pierce and feed the sender signal wires through and into the interior of the vehicle.

33. Go back to the interior and reach up into the back of the dash and pull the green sender wires through. Be sure to not pull too much and cause the wires in the engine compartment to become taunt.

34. Use the remaining two butt-splice connectors and crimp the green signal wires from the gauge senders to the green wires from the Marshall gauges. Ziptie the excess wires up and out of the way then reinstall your kick panel, door molding and trim.

35. Make a thorough check of the engine compartment to make sure all the wires are ziptied out of the way and no tools have been left lying around. Reconnect your negative battery terminal and start the vehicle. The Marshall gauges should turn on with the ignition and the needle will make a complete sweep then start reading normally. Take a flashlight and shine it down at the sandwich adapter to make sure there are no oil leaks occurring. If everything checks out, re-install the aluminum under engine panel, remove the jack stands, lower the car, remove the wheel chocks and go for a drive!

Parts Included:

Tools Required:

Procedure

Let's get started